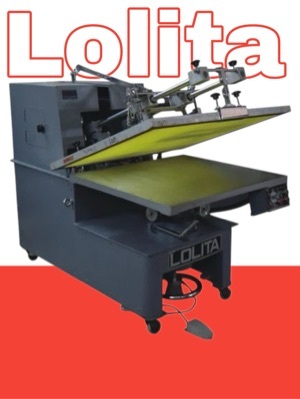

About Screen printing machine

The flatbed screen printing machine is highly versatile and used across numerous industries for printing on a wide array of flat surfaces. Paper and Cards: Widely used for printing on paper, cardboard, and specialty items like wedding cards and brochures. Plastics and Films: Effective for printing on PVC films, plastic sheets, membrane switches, and control panels. Industrial Materials: Capable of printing on flat objects made of metal, glass, wood, and PCBs (Printed Circuit Boards). Textiles: Used for printing on various fabrics, including cotton, silk, and non-woven bags. Specialty Applications: Can be used for specific finishing jobs like UV spot coating, adding a glossy or matte finish to printed materials.

Reliable Performance for Diverse Printing NeedsOur screen printing machine's strong MS construction ensures long-term reliability, making it ideal for businesses seeking durable equipment. Its various size options accommodate everything from small custom jobs to large volume orders. Efficient and easy to use, it is well-suited for multiple materials and offers stable operation throughout extended production cycles.

User-Friendly and Energy-Efficient DesignWith power consumption only between 220 and 340 watts, this semi-automatic screen printer balances energy use with performance. Its non-computerized operation simplifies the process, making it accessible to workers of varying skill levels. The semi-automatic feature provides enhanced control without sacrificing productivity, streamlining the printing process.

FAQ's of Screen printing machine:

Q: How does the semi-automatic screen printing machine operate?

A: The machine works by manually placing the screen and substrate, after which the semi-automatic mechanism controls the squeegee movement for even ink transfer. This simplifies the process, ensuring greater control and consistent printing results, especially for repetitive or batch jobs.

Q: What materials can be printed using this screen printing machine?

A: Our machine is suitable for a wide range of surfaces including paper, fabric, plastics, metal sheets, and more. The MS (Mild Steel) body and screen printer plate support various printing applications, making it versatile for different industries.

Q: What are the available size options for this machine?

A: The machine comes in several size variants: 18x24, 20x30, 22x32, 28x40, and 40x60 inches, allowing you to select a model that best suits your production scale and material dimensions.

Q: When is screen printing preferred over digital printing?

A: Screen printing is often preferred when producing bulk orders, vibrant and long-lasting prints, or when working with materials and inks not supported by most digital printers. It excels in applications needing durable and consistent output.

Q: Where is this machine manufactured and supplied?

A: This screen printing machine is manufactured and supplied within India, making it a practical option for local businesses needing reliable support and accessible service.

Q: What is the process for setting up and using the screen printing machine?

A: Set up involves selecting the correct size plate, arranging the screen, substrate, and ink, then initiating the semi-automatic mechanism. Regular cleaning and maintenance are recommended to ensure long-lasting performance.

Q: What are the key benefits of using this semi-automatic screen printing machine?

A: Key benefits include robust MS construction, adaptable sizing, energy efficiency, a straightforward non-computerized interface, and the ability to handle various materials. This results in reliable, cost-effective, and high-quality printing outcomes.